Ceramic Applicator Block: The Key to Perfect Ceramic Coating Application

In the world of car detailing, precision and efficiency are paramount. The ceramic applicator block stands out as an indispensable tool for achieving a flawless ceramic coating finish. Its design ensures even application, enhancing both the durability and appearance of protective layers on vehicles.

What is a Ceramic Applicator Block?

A ceramic applicator block is a specialized tool used to evenly spread ceramic coatings over a car's surface. Made from materials like foam or microfiber, these blocks ensure the coating adheres properly, providing long-lasting protection and a sleek, glossy finish.

Why Use a Ceramic Applicator Block?

Applying ceramic coatings without the right tool can lead to uneven coverage, streaks, or product waste. Ceramic applicator blocks are engineered to prevent these issues, delivering professional results every time.

Key Advantages:

- Uniform Application: Guarantees even distribution of ceramic coating across the surface.

- Minimized Waste: Helps conserve product by spreading it efficiently.

- Ease of Use: Ergonomic designs make the application process comfortable and precise.

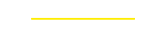

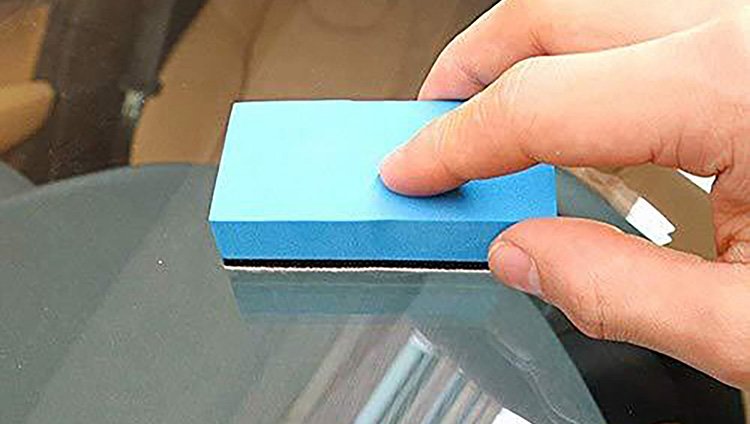

The Anatomy of a Ceramic Applicator Block

Ceramic applicator blocks typically feature:

- Core Material: Often foam for flexibility and even pressure distribution.

- Covering: Microfiber wraps or suede cloth for smooth application on sensitive surfaces.

- Ergonomic Design: Shapes that allow a firm grip, ensuring precision.

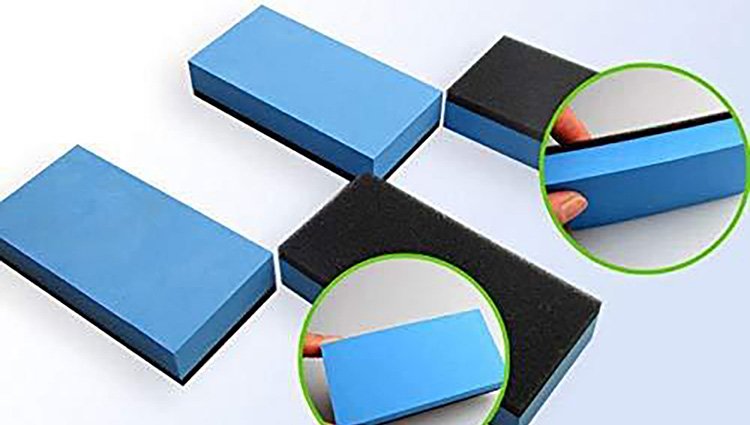

Using a Ceramic Applicator Block for Car Detailing

Step-by-Step Guide:

- Prepare the Surface: Clean and decontaminate the car thoroughly.

- Apply Coating to the Block: Place a few drops of ceramic coating onto the applicator’s surface.

- Spread Evenly: Work in small sections, using straight-line motions to ensure uniform coverage.

- Buff Off Excess: Use a clean microfiber towel to remove excess coating before it cures.

- Inspect for Flaws: Check for streaks or high spots and address them immediately.

Common Mistakes When Using Ceramic Applicator Blocks

- Using Too Much Product: Over-application can lead to uneven results or wasted coating.

- Skipping Surface Prep: Failing to clean the surface thoroughly reduces coating adhesion.

- Ignoring Timing: Allowing the coating to cure improperly can cause streaks or haze.

How Ceramic Applicator Blocks Work

The block’s smooth, absorbent surface allows the ceramic coating to spread evenly without soaking up excess product. This ensures maximum contact with the car’s surface, resulting in enhanced gloss and durability.

Tips for First-Time Users of Ceramic Applicator Blocks

- Start Small: Practice on an inconspicuous area to perfect your technique.

- Use Quality Coatings: Pair the block with high-quality ceramic products for the best results.

- Maintain Consistency: Apply even pressure to avoid streaks or uneven layers.

Why Professionals Prefer Ceramic Applicator Blocks

Professional detailers value ceramic applicator blocks for their ability to deliver consistent, high-quality results. The precision and control these tools offer make them essential for both beginners and seasoned experts.

Conclusion

The ceramic applicator block is a must-have for anyone serious about car detailing. Its design, efficiency, and ease of use make it an essential tool for achieving a flawless ceramic coating application. Whether you’re a DIY enthusiast or a professional detailer, investing in a quality ceramic applicator block ensures your car's finish remains protected and pristine.

-

Ceramic Applicator Block: The Key to Perfect Ceramic Coating Application

In the world of car... - Category: Mafra

- Stock:In Stock

- Ceramic Applicator Block